The launch of the world's first wood-panelled satellite marks a significant step forward in testing sustainable building materials for future space exploration. Developed by researchers at Kyoto University in Japan, the satellite, known as LignoSat, weighs only 900 grams and is designed to operate for six months by orbiting the Earth. This pioneering initiative seeks to explore the viability of timber, specifically magnolia wood, as a renewable alternative to metals commonly used in satellite construction.

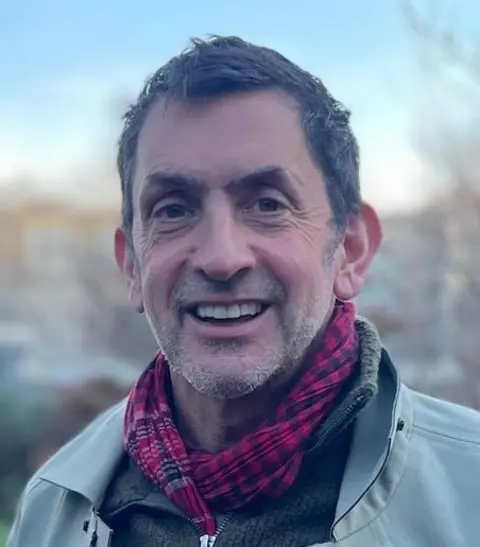

LignoSat is part of a SpaceX mission to the International Space Station, from where it will be deployed into orbit. Utilizing traditional craftsmanship methods that avoid screws and glue, the satellite's wood panels present a novel approach to space engineering. Professor Koji Murata, a forest science expert at Kyoto University, explains that wood's resilience in the absence of moisture and oxygen could make it a more durable option for space applications compared to terrestrial usage.

The concept aligns with a vision where extraterrestrial environments like the Moon or Mars could potentially be utilized for growing trees, allowing construction materials for future colonies. Although LignoSat's panels are not entirely wood-based—combining traditional aluminum structures and electronic components—it reflects a broader ambition to innovate with more sustainable resources in space technology.

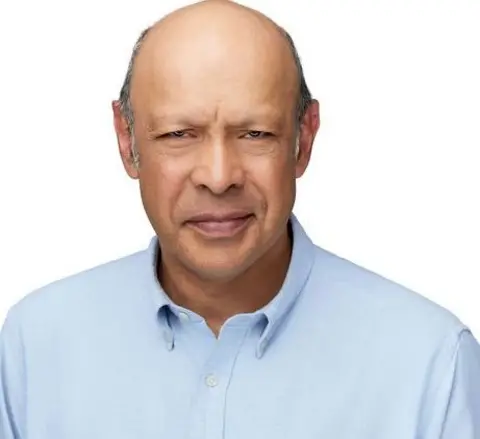

Dr. Simeon Barber, an expert from the Open University in the UK, emphasizes that while LignoSat may be a breakthrough, using wood in spacecraft does pose engineering challenges due to the material's unpredictable properties. However, he highlights that the exploration of such renewable materials could lead to significant reductions in pollution when satellites burn up upon re-entry.

This initiative comes amid growing concerns about space debris, with the satellite's design aiming to minimize the environmental impact of end-of-life space technology. Despite skepticism regarding the practicality of wooden constructs in critical spacecraft structures, LignoSat's launch represents a forward-thinking approach to melding ecological sustainability with the future of space exploration. As the field continues to grapple with pollution issues, the implications of incorporating wood may lead to greener solutions in an evolving industry.

LignoSat is part of a SpaceX mission to the International Space Station, from where it will be deployed into orbit. Utilizing traditional craftsmanship methods that avoid screws and glue, the satellite's wood panels present a novel approach to space engineering. Professor Koji Murata, a forest science expert at Kyoto University, explains that wood's resilience in the absence of moisture and oxygen could make it a more durable option for space applications compared to terrestrial usage.

The concept aligns with a vision where extraterrestrial environments like the Moon or Mars could potentially be utilized for growing trees, allowing construction materials for future colonies. Although LignoSat's panels are not entirely wood-based—combining traditional aluminum structures and electronic components—it reflects a broader ambition to innovate with more sustainable resources in space technology.

Dr. Simeon Barber, an expert from the Open University in the UK, emphasizes that while LignoSat may be a breakthrough, using wood in spacecraft does pose engineering challenges due to the material's unpredictable properties. However, he highlights that the exploration of such renewable materials could lead to significant reductions in pollution when satellites burn up upon re-entry.

This initiative comes amid growing concerns about space debris, with the satellite's design aiming to minimize the environmental impact of end-of-life space technology. Despite skepticism regarding the practicality of wooden constructs in critical spacecraft structures, LignoSat's launch represents a forward-thinking approach to melding ecological sustainability with the future of space exploration. As the field continues to grapple with pollution issues, the implications of incorporating wood may lead to greener solutions in an evolving industry.